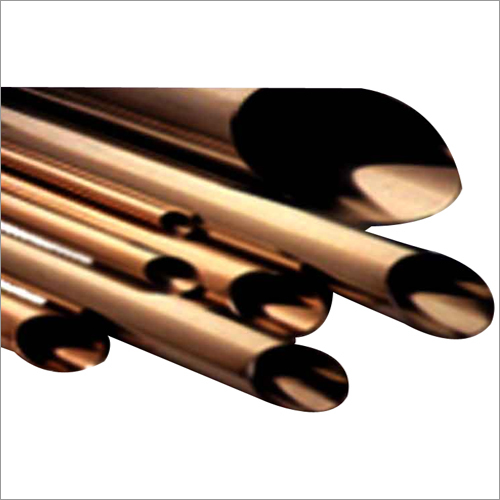

90-10 Cupro Nickel

90-10 Cupro Nickel Specification

- Size

- Customizable

- Outer Diameter

- Available up to 100 mm (for tubes)

- Cross Dimension

- As specified

- Surface Treatment

- Bright / Annealed / Polished

- Diameter

- Available up to 100 mm (for tubes)

- Finish

- Hot Rolled / Cold Rolled / Polished

- Condition

- New

- Product Type

- Plate / Sheet / Coil / Strip / Tube

- Shape

- Sheet, Plate, Strip, Tube, Coil

- Strength

- Good tensile strength

- Hardness

- 65-120 HV

- Alloy

- 90/10 Cupro Nickel (CuNi10Fe1Mn)

- Grade

- C70600 / CN102

- Length

- Custom or as required

- Width

- Custom or as required

- Thickness

- 0.5 mm - 20 mm

- Color

- Silver (Metallic)

- Melting Point

- 1100C

- Thermal Conductivity

- 40 W/mK

- Density

- 8.94 g/cm

- Formability

- Excellent

- Magnetism

- Non-magnetic

- Electrical Resistivity

- 0.199 m

- Machinability

- Fair

- Corrosion Resistance

- Excellent in seawater and steam

- Applications

- Heat exchangers, condensers, marine hardware, piping

- Standard

- ASTM B122 / B171 / B466 / B467

90-10 Cupro Nickel Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Per Month

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

About 90-10 Cupro Nickel

Feature

- 90/10 Cupro Nickel is widely used in sea water. It has very good corrosion resistance to clean moderately polluted marine or estuary water, even containing dissolved incondensable gases.

- This alloy is virtually immune from stress-corrosion cracking and hot spot denickelification.

- In clean sea water, a velocity of up 2.2-2.5 m/s (7.5-8.5 ft/s) is accepted while 4 m/s (13 ft/s) is the upper limit for clean fresh or slightly saline solutions.

- To avoid the risk of deposit attack, it is generally recommended to never operate at water velocities below about 0.8-1 m/s (2.5-3.5 ft/s). 90/10 Cupro Nickel can also be used, with appropriately reduced flow velocity, in contact with water containing some sulphides or suspended solids. It is also often selected for its good mechanical properties, both at room and relatively elevated temperatures.

CU-NI 90/10 TUBES SPECIFICATIONS

| Specifications | ASTM B 111, B543, B552 ASME SB 111, SB543, SB552 |

| Dimensions | ASTM, ASME and API |

| Size | 1/2 TO 6 IN OD & NB IN Various SWG & SCH |

| Specialized in | Large Diameter Size |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

TYPES OF CU-NI 90/10 TUBES

| Cupro Nickel 90/10 Seamless Tubes | 90/10 Cu-Ni Seamless Pipes |

| UNS C70600 Seamless Tubes | WERKSTOFF NR. 2.0872 Seamless Tubes |

| ASTM B111 90/10 Cupro Nickel Seamless Tubes | Cu-Ni 90/10 Welded Tubes |

| 90/10 Cupro Nickel Welded Tubes | UNS C70600 Welded Tubes |

| WERKSTOFF NR. 2.0872 Welded Tubes | ASTM B552 90/10 Cupro Nickel Welded Tubes |

| Copper Nickel 90/10 ERW Tubes | Cupro Nickel 90/10 EFW Tubes |

| Cupro Nickel 90/10 Round Tubes | 90/10 Cupro Nickel Cu Round Tubes |

| UNS C70600 Round Tubes | Copper Nickel UNS C70600 Round Tubes |

| Cupro Nickel 90/10 Fabricated Tubes | 90/10 Cu-Ni Fabricated Tubes |

CHEMICAL COMPOSITION OF CU-NI 90/10 TUBES

| Element | Cu-Ni 90/10 |

| Cu | 88.6 min |

| Pb | 0.05 max |

| Mn | 1.0 max |

| Fe | 1.8 max |

| Zn | 1 max |

| Ni | 9-11 max |

CU-NI 90/10 TUBES MECHANICAL PROPERTIES

| Element | Cu-Ni 90/10 |

| Density | 8.1 g/cm3 |

| Melting Point | 1443 C (2430 F) |

| Yield Strength (0.2%Offset) | Psi 35,000, MPa 241 |

| Tensile Strength | Psi -80,000, MPa -551 |

| Elongation | 30% |

CUPRO NICKEL 90/10 TUBES EQUIVALENT GRADES

| STANDARD | Cupro Nickel 90/10 |

| UNS | C70600 |

| WERKSTOFF NR. | 2.0872 |

Superior Corrosion Resistance in Marine Applications

The 90-10 Cupro Nickel alloy stands out for its remarkable resistance to seawater and steam corrosion, making it a reliable choice for heat exchangers, condensers, and marine piping. Its robust performance ensures minimal degradation over time, even in harsh coastal or industrial settings.

Customizable Forms and Dimensions Available

This alloy can be tailored to various requirements, available as plates, sheets, strips, tubes, and coils with thickness ranging from 0.5 mm to 20 mm and tube diameters up to 100 mm. Surface treatments such as bright, annealed, or polished finishes provide flexibility for different operational needs and aesthetics.

FAQs of 90-10 Cupro Nickel:

Q: How is 90-10 Cupro Nickel processed to achieve different finishes and forms?

A: 90-10 Cupro Nickel is manufactured through processes such as hot rolling, cold rolling, and annealing, resulting in sheet, plate, strip, tube, or coil forms. Surface treatments like bright, annealed, or polished are applied to meet specific requirements or enhance appearance.Q: What are the main benefits of using 90-10 Cupro Nickel in marine environments?

A: This alloy offers exceptional corrosion resistance to seawater and steam, non-magnetic properties, and stable mechanical performance, making it ideal for marine hardware, piping, condensers, and heat exchangers, where durability and longevity are critical.Q: When is 90-10 Cupro Nickel recommended over other alloys for piping or tubing?

A: 90-10 Cupro Nickel is preferred in marine, power generation, and chemical processing sectors when corrosion resistance against aggressive media like seawater is essential, especially where non-magnetic properties and reliable performance are required.Q: Where are 90-10 Cupro Nickel products commonly exported from and supplied?

A: Manufacturers, suppliers, and exporters in India offer 90-10 Cupro Nickel products worldwide, delivering materials to shipbuilding, oil and gas, and industrial sectors conforming to ASTM standards.Q: What is the process to customize the size and shape of 90-10 Cupro Nickel products?

A: Custom sizing is achieved by specifying length, width, thickness, cross dimensions, and outer diameter (for tubes) to meet precise project requirements. The alloy is fabricated and finished according to these specifications.Q: How does the formability and machinability of 90-10 Cupro Nickel affect its usage?

A: With excellent formability and fair machinability, this alloy can be easily shaped, bent, or joined for complex assemblies. It provides versatility in manufacturing pipes, tubes, and other structural components.Q: What are the electrical and thermal properties of 90-10 Cupro Nickel?

A: The density is 8.94 g/cm, electrical resistivity is 0.199 m, and thermal conductivity is 40 W/mK, supporting efficient heat transfer in heat exchangers and consistent performance in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cupro Nickel Products Category

Cupro-Nickel Pipe Fitings

Grade : CuNi 90/10 (C70600), CuNi 70/30 (C71500)

Hardness : 80160 HB

Alloy : Other, CopperNickel (CuNi) alloy

Color : Metallic Copper

Product Type : Other, Pipe Fittings

Shape : Other, Elbow, Tee, Reducer, End Cap, Union

95-5 Copper Nickel

Grade : Grade A

Hardness : Medium

Alloy : 955 Copper Nickel, Other

Color : Copper

Product Type : Tube, Other

Shape : Round

Copper Nickel Round Bars

Grade : Standard

Hardness : High

Alloy : Other, Copper Nickel

Color : Silver

Product Type : Other, Round Bars

Shape : Round

Automotive Break Tubings

Grade : High Grade

Hardness : Medium

Alloy : Copper, Other

Color : Golden

Product Type : Automotive Brake Tubing, Other

Shape : Other, Tubular Round

|

MULTI ALLOYS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry