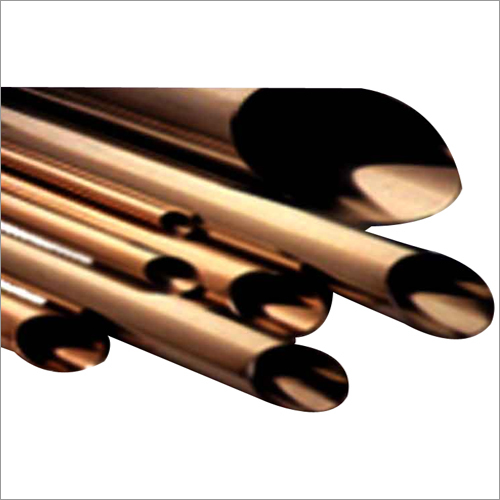

Cupro Nickel

Cupro Nickel Specification

- Surface Treatment

- Polished

- Product Type

- Other

- Shape

- Round

- Hardness

- Yes

- Alloy

- No

- Grade

- Domestic & Commercial

- Color

- reddish-brown

- Warranty

- 1 Year

Cupro Nickel Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About Cupro Nickel

Feature

7030 Cupro Nickel is mainly preferred when the severity of service condition Cooling water steam condensate temperature etc is such as to virtually rule out all other copper metals

Due to its hardness and to the type of oxide whereby its surface is selfprotected 7030 Cupro Nickel has excellent resistance to impingement and erosioncorrosion by of suspended solids in sea water flowing at up to 335 ms 10115 ft s

Like all Cupronickels 7030 Cupro Nickel is virtually immune from stresscorrosion cracking

It can be very sensitive to deposit attack and is therefore not recommended for stagnant or slow moving under 1 12 ms or 354 fts water

7030 Cupro Nickel is very widely employed in water desalination plants especially in the most critical areas such as the heat reject and brine heater stages as well as in the under cooling areas of power station condensers in the chemical petrochemical and food processing industries and more generally in all applications where top corrosion resistance is required from both the shell and tube side

PRODUCT APPLICATION AREAS

Chillers

Heat Condensers Exchangers

Power Plants

Refineries

Desalination Plants

Ship Building Ship Repairs

Defence

High Capacity Power Plants

Distiller Tubes

Evaporators Ferrules

SIZE

12 to 6 in OD NB in various SWG SCH

FORM

Round square rectangular coil u shape pan cake hydraulic

LENGTH

Single random double random required length

END

Plain end beveled end threaded

MATERIALS

Copper nickel CuNi Seamless Tube C 70600 CU NI 9010 C 71500 CU NI 7030

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cupro Nickel Products Category

Cupro-Nickel Pipe Fitings

Color : Metallic Copper

Length : As per requirement (customizable)

Surface Treatment : Other, Polished/Annealed

Alloy : Other, CopperNickel (CuNi) alloy

Strength : High tensile strength suitable for marine applications

Thickness : 0.5 mm to 8 mm

90-10 Cupro Nickel

Color : Silver (Metallic)

Length : Custom or as required

Surface Treatment : Other, Bright / Annealed / Polished

Alloy : Other, 90/10 Cupro Nickel (CuNi10Fe1Mn)

Strength : Good tensile strength

Thickness : 0.5 mm 20 mm

Copper Nickel Round Bars

Color : Silver

Length : Customizable

Surface Treatment : Polished

Alloy : Other, Copper Nickel

Strength : High

Thickness : Standard

95-5 Copper Nickel

Color : Copper

Length : Standard

Surface Treatment : Polished

Alloy : 955 Copper Nickel, Other

Strength : High

Thickness : Varied

|

MULTI ALLOYS INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry